Call for research cooperation

THE CHALLENGE

Designing and code-checking steel connections have been one of the most vibrant topics across academia and the engineering industry in the last decade. In 2014, Czech Technical University in Prague and software company IDEA StatiCa created a method for designing steel connections called Component-based Finite Element Method (CBFEM).

This approach has been successfully verified and validated through numerous verification examples, validation studies, and live tests. It has also been widely adopted by the engineering community – software packages based on the CBFEM method (IDEA StatiCa Connection, HILTI Profis Engineering) are used by thousands of engineers around the world.

We are now looking for a research partner to continue and deepen the verification and validation of the CBFEM approach according to the AISC standards as well as to further develop and improve the underlying material models.

Profile of the desired research partner

Department of structural engineering of a US-based university, preferably focused on steel, ideally connections. Research partner would carry out a set of verification and validation examples and formulate recommendations to ensure the maximum possible applicability according to AISC standards. Verification works are coordinated by the team of prof Wald at CTU. All necessary support related to the software is to be provided by IDEA StatiCa team.

All verification works are to be funded by IDEA StatiCa based on a contract with the research partner.

Typical verification example structure

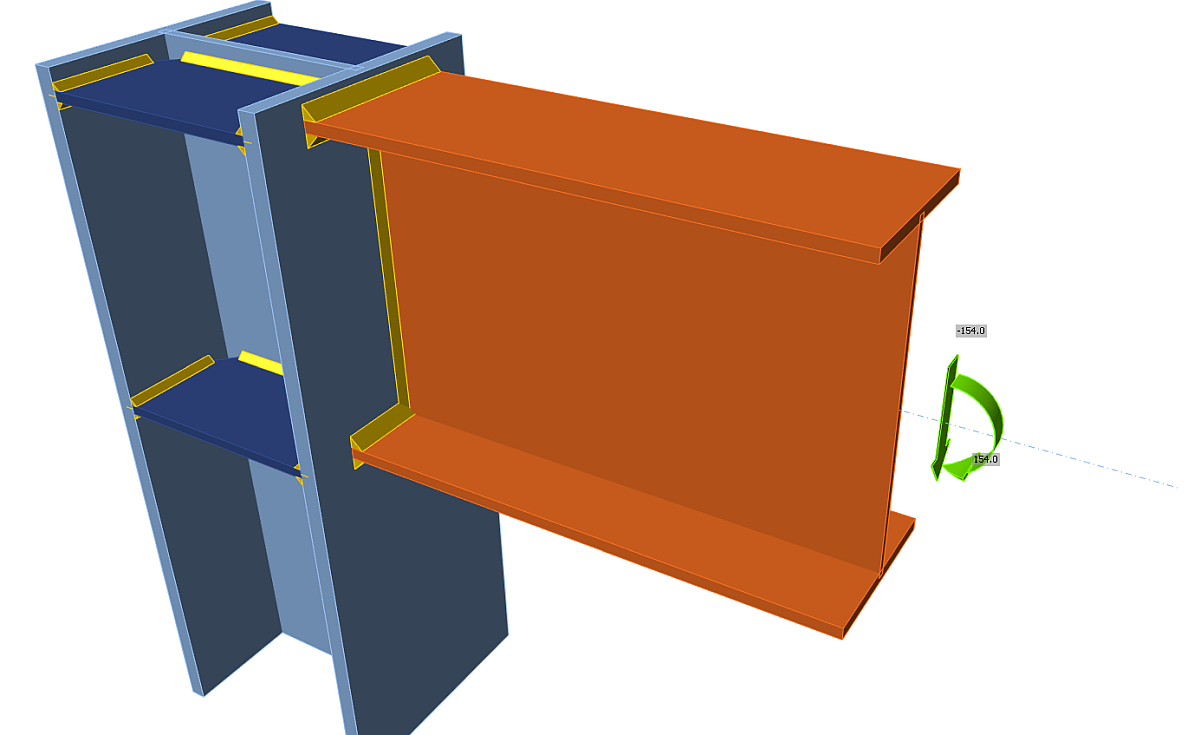

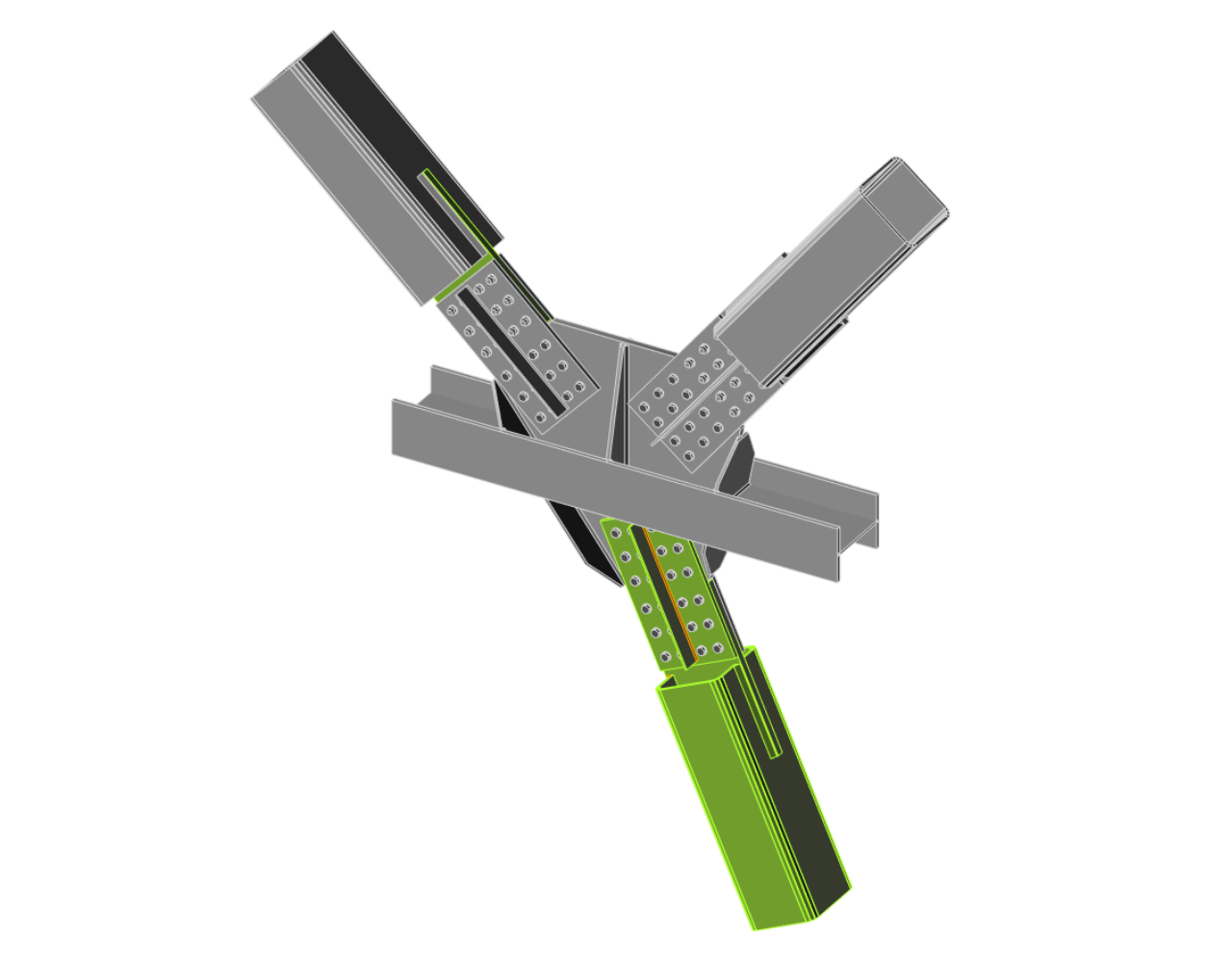

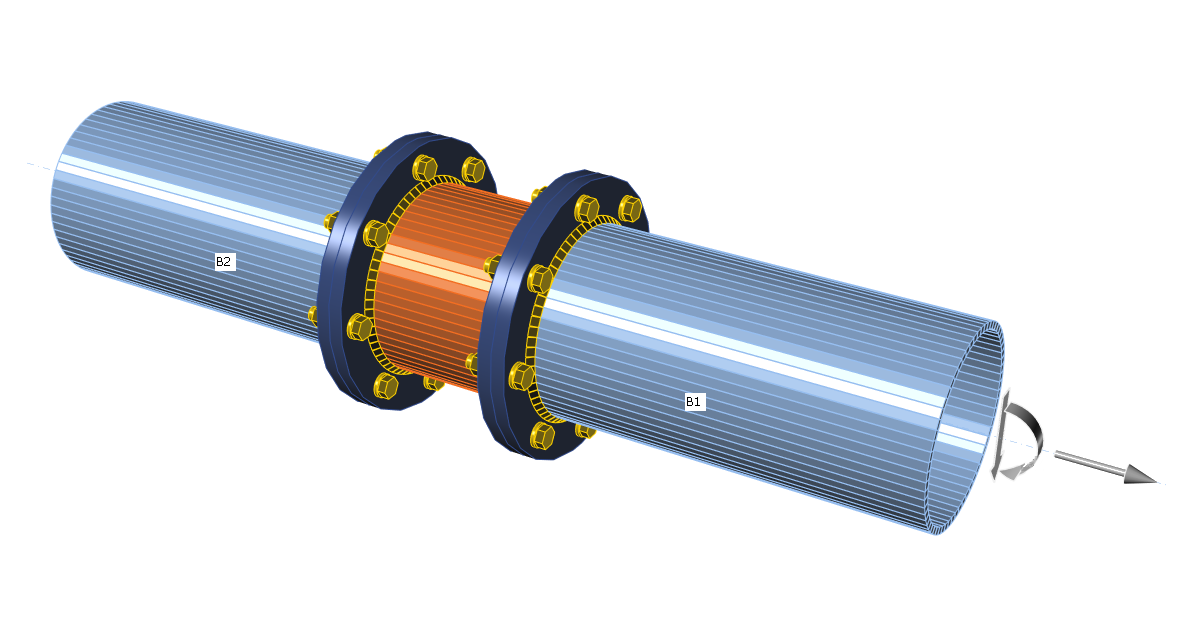

- Description of the connection - pictures, type

- Description of the analytical model - hand-calcs, assumptions, clauses from AISC

- Description of the CBFEM model - how it works, differences to the analytical model

- Verification of the CBFEM model

- Sensitivity analysis – tables and graphs for various parameters, e.g. steel grade, beam section, endplate thickness, etc. Comparison of the results according to CBFEM and the analytical model

- Conclusion – explain differences (if any) caused by simplifications in the analytical model, axis of rotation, weld stress assumptions, etc.

Our philosophy of testing

The validation and verification process confirms that the results of the software are correct. Verification is a comparison to an analytical method, most often incorporated in a code (e.g. AISC 360-16). Validation is a comparison of a numerical model to an experiment. The numerical model is often highly advanced, including material and geometrical nonlinearities. The results of the numerical model are compared to those of CBFEM. The results do not need to coincide perfectly but the CBFEM results must be safe.

Verification book by prof Wald

Currently, the most thorough set of verification examples is done for Eurocode (EN1993-1-8:2005). Team of professor Wald have summarized the most relevant verifications and explanations in the book called "Component-based finite element design of steel connections". This cooperation should aspire to create something similar for the AISC.

Coordinators

Successful R&D projects

Our most important R&D projects from recent years combine academic excellence and software development to deliver innovative tools for structural engineers. We are building an international network of experts who contribute to better tools for structural engineering.