6.2.1 Description

The objective of this study is a verification of component based finite element method (CBFEM) of a beam-column joint with a class 4 column web with research FEM model (RFEM) and component method (CM).

6.2.2 Analytical model

The component column web panel in shear is described in cl. 6.2.6.1 EN 1993-1-8:2005. The design method is limited to column web slenderness d / tw ≤ 69 ε. Webs with higher slenderness are designed according to EN 1993-1-5:2006 cl. 5 and Annex A. The shear resistance is made of shear buckling resistance of the web panel and resistance of the frame made of the flanges and stiffeners surrounding the panel. The buckling resistance of the web panel is based on the shear critical stress

Fig. 6.2.1 Research FEM model of a beam-column joint with slender column panel

6.2.4 Design finite element model

The design procedure for slender plates is described in section 3.10. The buckling analysis is implemented in the software. The calculation of the design resistances is done according to design procedure. FCBFEM is interpolated by the user until ρ · αult,k/γM1 is equal to 1.

A beam-column joint with a slender column web is studied. The height of the beam web is changing, thus the width of the column web panel is changing. The geometry of the examples is described in Tab. 6.2.1. The joint is loaded by bending moment.

Tab. 6.2.1 Examples overview

6.2.5 Global behaviour and verification

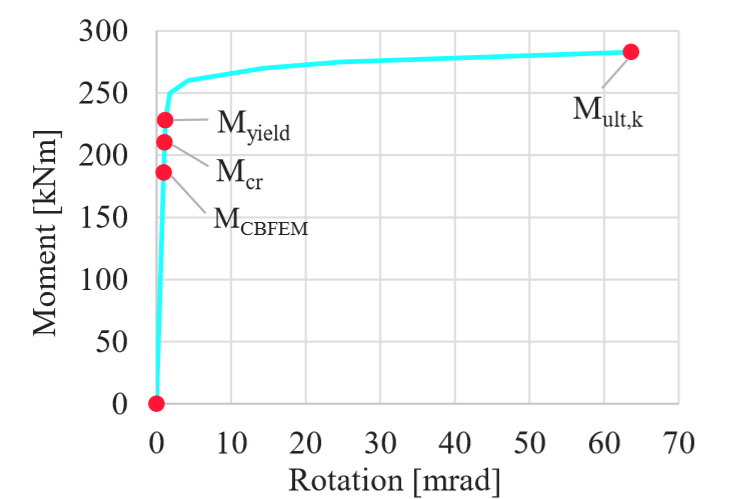

The global behaviour of a beam-column joint with slender column web described by moment-rotation diagram in CBFEM model is shown in Fig. 6.2.2. Attention is focused to the main characteristics: design resistance and critical load. The diagram is completed with a point where yielding starts and resistance by 5 % plastic strain.

Fig. 6.2.2 Moment-rotation curve of example IPE600

6.2.6 Verification of resistance

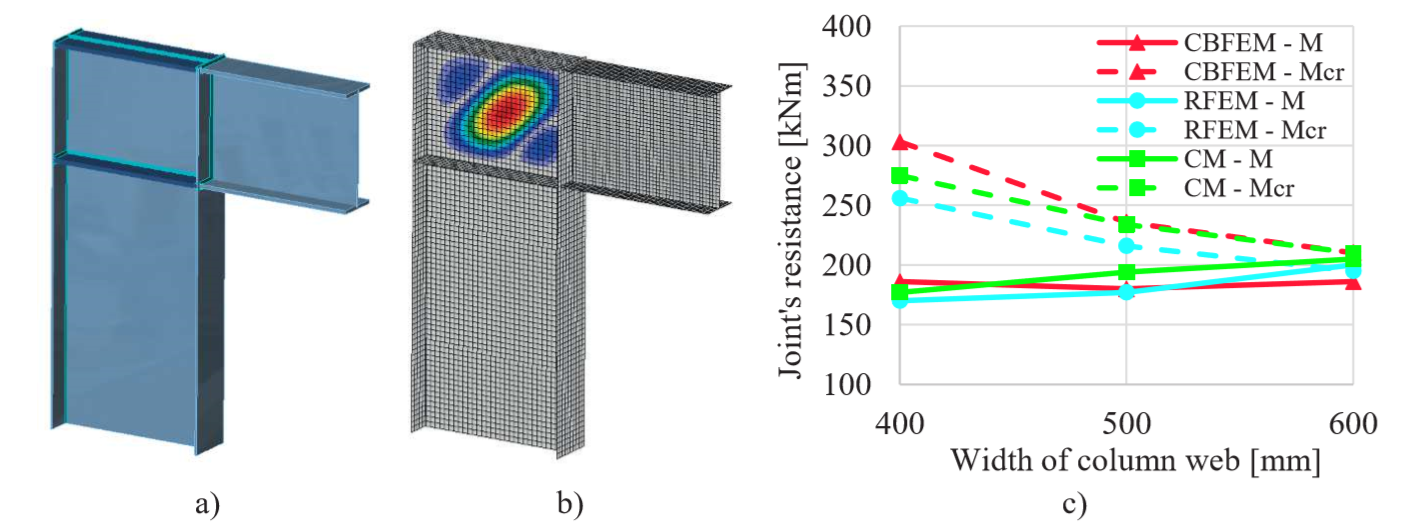

The design resistance calculated by CBFEM is compared with RFEM and CM. The comparison is focused on the design resistance and critical load. The results are ordered in Tab. 6.2.2. The diagram in Fig. 6.2.3c shows the influence of the width of the column web on the resistances and critical loads in the examined examples.

Tab. 6.2.2 Design resistances and critical loads of RFEM, CBFEM and CM

The results show good agreement in critical load and design resistance. The CBFEM model of the joint with a beam IPE600 is shown in Fig. 6.2.3a. The first buckling mode of the joint is shown in Fig. 6.2.3b.

Fig. 6.2.3 a) CBFEM model b) First buckling mode

c) Influence of width of column web on resistances and critical loads

Verification studies confirmed the accuracy of the CBFEM model for prediction of a column web panel behaviour. Results of CBFEM are compared with the results of the RFEM and CM. The design procedure is verified on the RFEM model. Procedures predict similar global behaviour of the joint. The difference in design resistance is in all cases up to 10 %.

6.2.7 Benchmark example

Inputs

Beam

- Steel S235

- IPE600

Column

- Steel S235

- Flange thickness tf = 10 mm

- Flange width bf = 250 mm

- Web thickness tw = 4 mm

- Web height hw = 820 mm

Web stiffener

- Steel S235

- Stiffener thickness tw = 19 mm

- Stiffener width hw = 250 mm

- Stiffeners opposite to upper and lower flange

Outputs

- Load by 5 % plastic strain Mult,k = 283 kNm

- Design resistance MCBFEM = 186 kNm

- Critical buckling factor (for M = 186 kNm) αcr = 1,13

- Load factor by 5 % plastic strain αult,k = Mult,k / MCBFEM = 283/186 = 1,52