5.3.1 Description

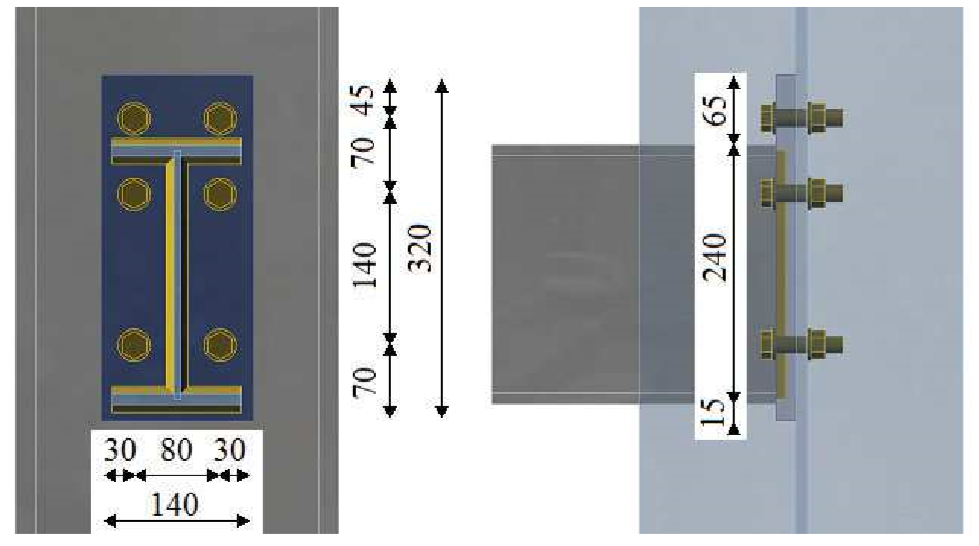

ln the Chapter is verified the Component based finite element method (CBFEM) model of the beam to column joint on Component method (CM). The extended end plate with three bolt rows is connected to column web and loaded by bending moment, see Fig. 5.3.1.

Fig. 5.3.1 Joint geometry

5.3.2 Analytical model

Three components, which are guiding the behaviour, are the end plate in bending, the beam flange in tension and in compression, and the column web in bending. The end plate and the beam flange in tension and in compression are designed according to EN 1993-1-8:2005. The behaviour of the column web in bending is predicted according to (Steenhuis et al., 1998). The results of experiments of the beam to column minor axis joints e.g. (Lima et al., 2009) shows the good prediction of this type of join loaded in plane of connected beam.

5.3.3 Numerical model

Assessment is based on the maximum strain given according to EN 1993-1-5:2006 by value of 5 %. Detailed information about CBFEM model is summarised in Chapter 3.

5.3.4 Verification of resistance

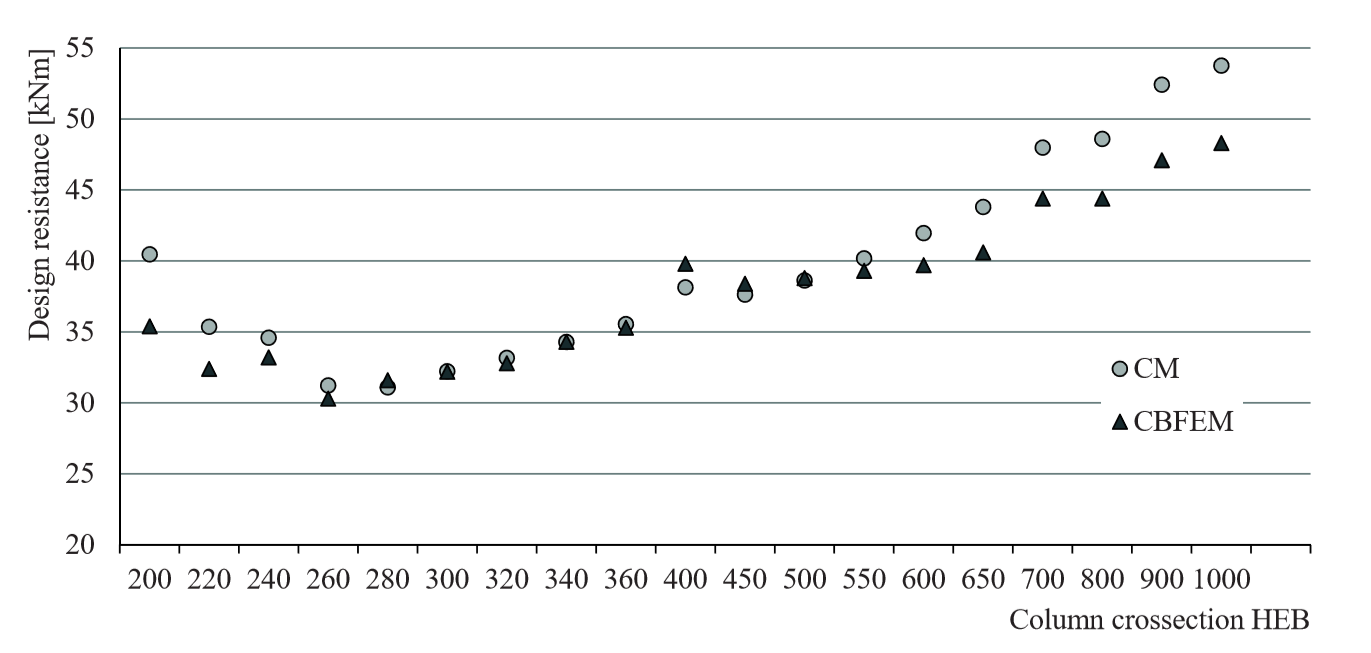

The sensitivity study of the joint resistance was prepared for column cross sections. Joint geometry is shown in Fig. 5.3.1. ln Tab. 5.3.1 and in Fig. 5.3.2 are summarised results of calculation in case of relatively enlarging of geometry of the end plate P18.

Tab. 5.3.1 Results of prediction of the of end plate minor axis connection for different rafters

Fig. 5.3.2 Comparison resistance of end plate minor axis connection predicted by CBFEM and CM

5.3.5 Global behaviour

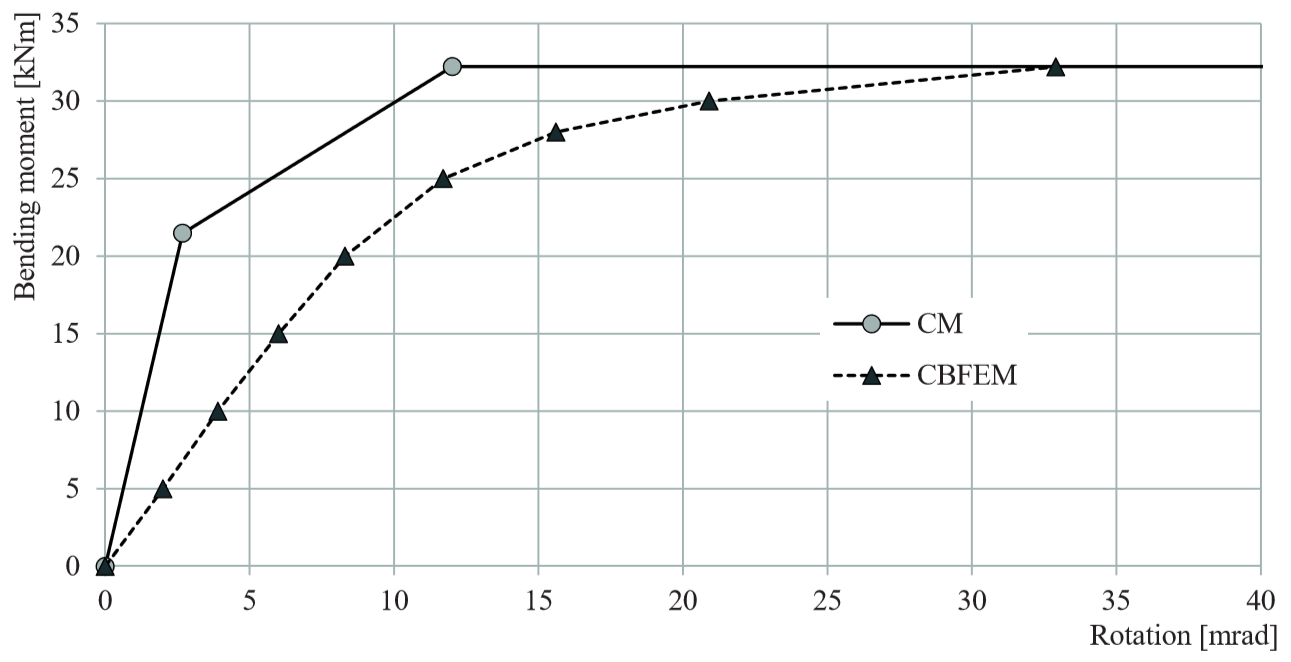

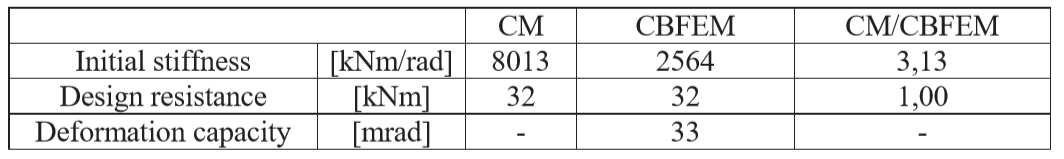

Global behaviour is presented on force-deformation curve. Beam lPE 240 is connected to column HEB 300 with six bolts M16 8.8. End plate geometry is shown in Fig. 5.3.1 and in Tab. 5.3.1. Comparison of both methods results is presented in Fig. 5.3.3 and in Tab.5.3.2. Both methods predict similar design resistance. CBFEM generally gives lower initial stiffness compared to CM.

Fig. 5.3.3 Prediction of behaviour of end plate minor axis connection on moment rotational curve

Tab. 5.3.2 Main characteristics for global behavior

Results of studies are summarized in graph comparing resistances by CBFEM and component method, see Fig. 5.3.4. The results show the difference of methods is up to 13 %. CBFEM predicts in all cases lower resistance compare to CM, which is based on simplification in (Steenhuis et al., 1998). Similar results may be observed in work by (Wang and Wang, 2012).

Fig. 5.3.4 Summary of verification of CBFEM to CM for the end plate minor axis connection

5.3.6 Benchmark example

The benchmark case is prepared for the end plate minor axis connection according to Fig. 5.3.1 with modified geometry as summarised below.

Inputs

- Steel S235

- Column HEB 300

- Beam lPE 240

- Bolts 6xM16 8.8

- Welds thickness 5 mm

- End-plate thickness tp = 18 mm

Outputs

- Design resistance in bending MRd = 32,2 kNm

- Guiding component - column web in bending