5.1.1. Description

The objective of this chapter is verification of component based finite element method (CBFEM) of T- stubs connected with two bolts loaded in tension with component method (CM) and research FEM model (RM) created in Midas FEA software.

5.1.2. Analytical model

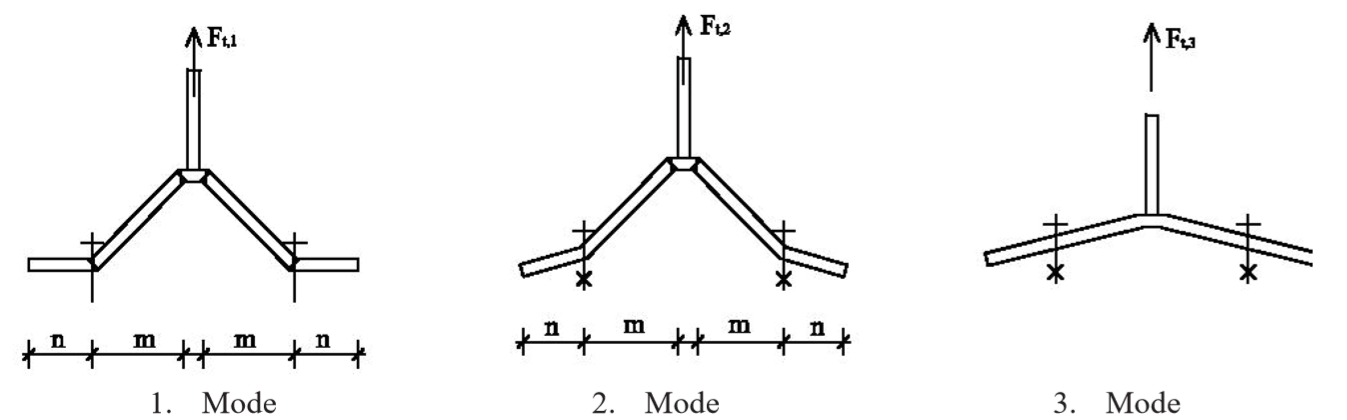

Welded T-stub and bolt in tension are components examined in the study. Both components are designed according to EN 1993-1-8:2005. The welds are designed not to be the weakest component. Effective lengths for circular and noncircular failures are considered according to EN 1993-1-8:2005 cl. 6.2.6. Only tension loads are considered. Three modes of collapse according to EN 1993-1-8:2005 cl. 6.2.4.1 are considered 1. mode with full yielding of the flange, 2. mode with two yield lines by web and rupture of the bolts and 3. mode for rupture of the bolts, see Fig. 5.1.1. Bolts are designed according to cl. 3.6.1 in EN 1993-1-8:2005. Design resistance considers punching shear resistance and rupture of the bolt.

Fig. 5.1.1 Collapse modes of T-stub

5.1.3. Design numerical model

T-stub is modelled by 4-nodes shell elements as described in Chapter 3 and summarised further. Every node has 6 degrees of freedom. Deformations of the element consist of membrane and flexural contributions. Nonlinear elastic-plastic material status is investigated in each layer of integration point. Assessment is based on the maximum strain given according to EN 1993-1-5:2006 by value of 5 %. Bolts are divided into three sub-components. The first is the bolt shank, which is modelled as a nonlinear spring and caries tension only. The second sub-component transmits tensile force into the flanges. The third sub-component solves shear transmission.

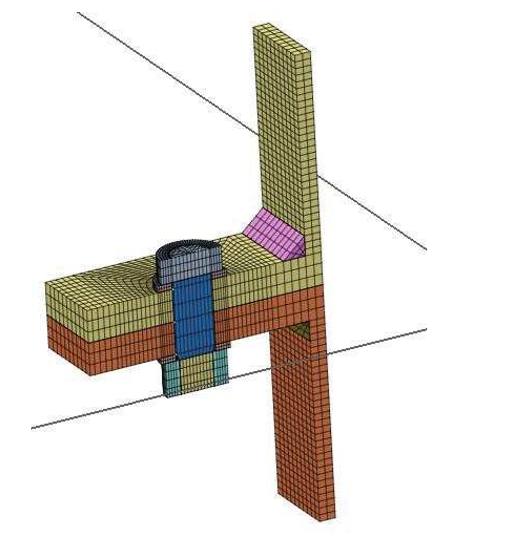

5.1.4. Research numerical model

ln cases, where the CBFEM gives method higher resistance, initial stiffness or deformation capacity. Research FEM model (RM) from brick elements validated on experiments (Godrich et al, 2013) is used to verify the CBFEM model. RM is created in Midas FEA software of hexahedral and octahedral solid elements, see Fig. 5.1.2 Mesh sensitive study was provided to reach proper results in adequate time. Numerical model of the bolts is based on the model by (Wu et al, 2012). The nominal diameter is considered in the shank and the effective core diameter is considered in the threaded part. Washers are coupled with the head and nut. Deformation caused by stripping of the threads in thread-nut contact area is modelled using interface elements. lnterface elements are unable to transfer tensile stresses. Contact elements allowing the transmission of pressure and friction are used between washers and flanges of the T-stub. One quarter of the sample was modelled using the symmetry.

Fig. 5.1.2 Research FEM model

5.1.5. Range of validity

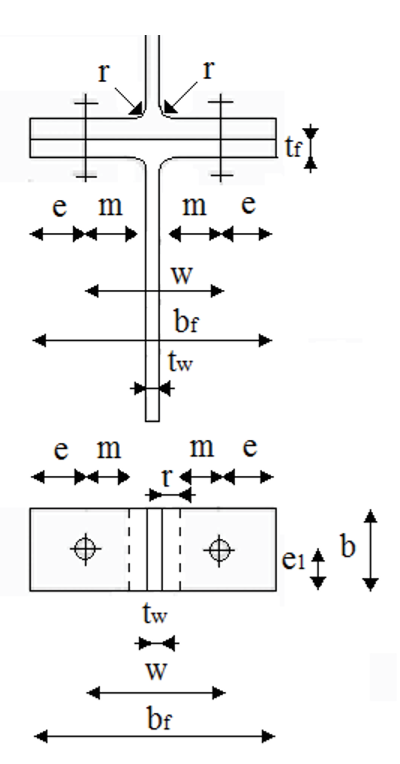

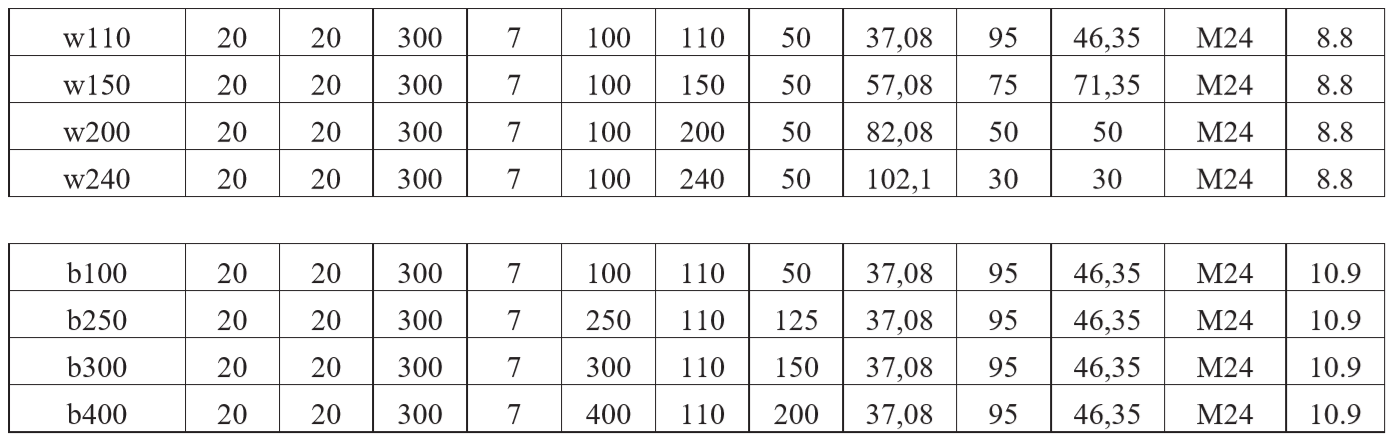

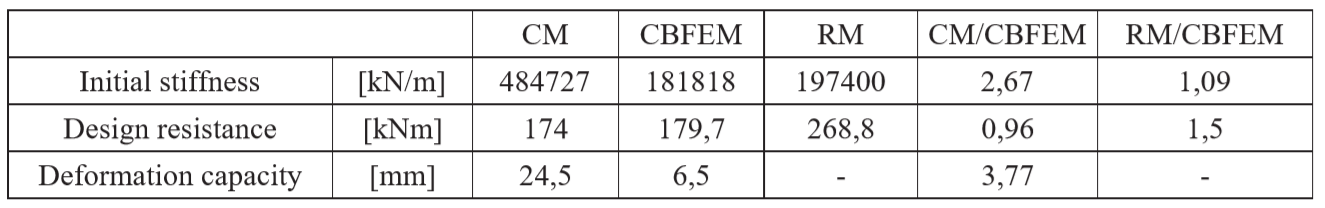

CBFEM was verified for the selected typical T-stub geometries. The minimal thickness of flange is 8 mm. Maximal distance of the bolts to bolt diameter is limited by p/db :S 20. The distance of the bolt line to web is limited to m/db :S 5. Overview of the considered samples with steel plates of S235 fy = 235 MPa, fu = 360 MPa, E = Ebolt = 210 GPa is shown in the Tab. 5.1.1 and in Fig. 5.1.3.

Fig. 5.1.3 Geometry of the T stubs

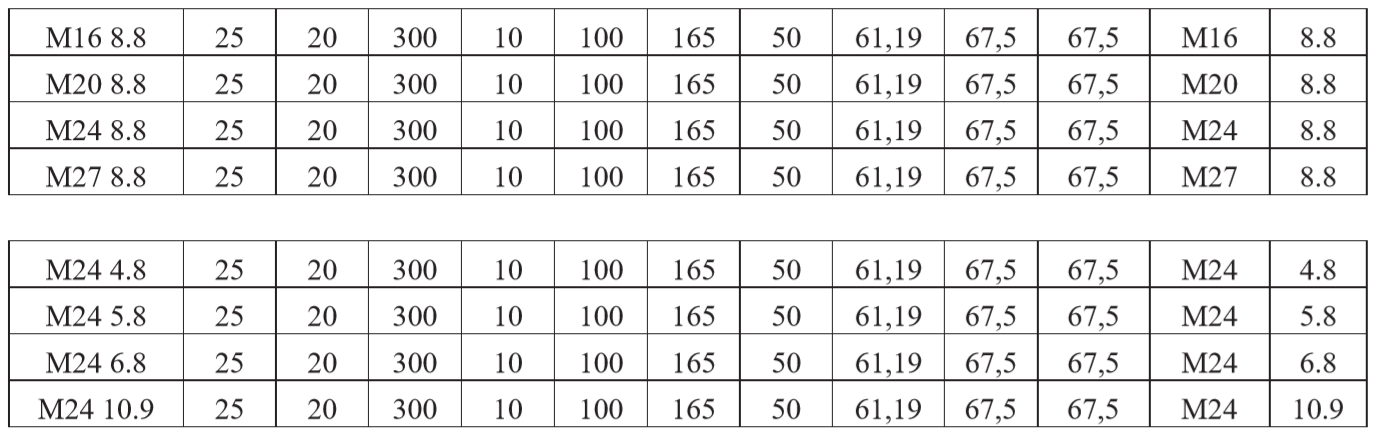

Tab. 5.1.1 Overview of the considered samples of T stubs

5.1.6. Global behaviour

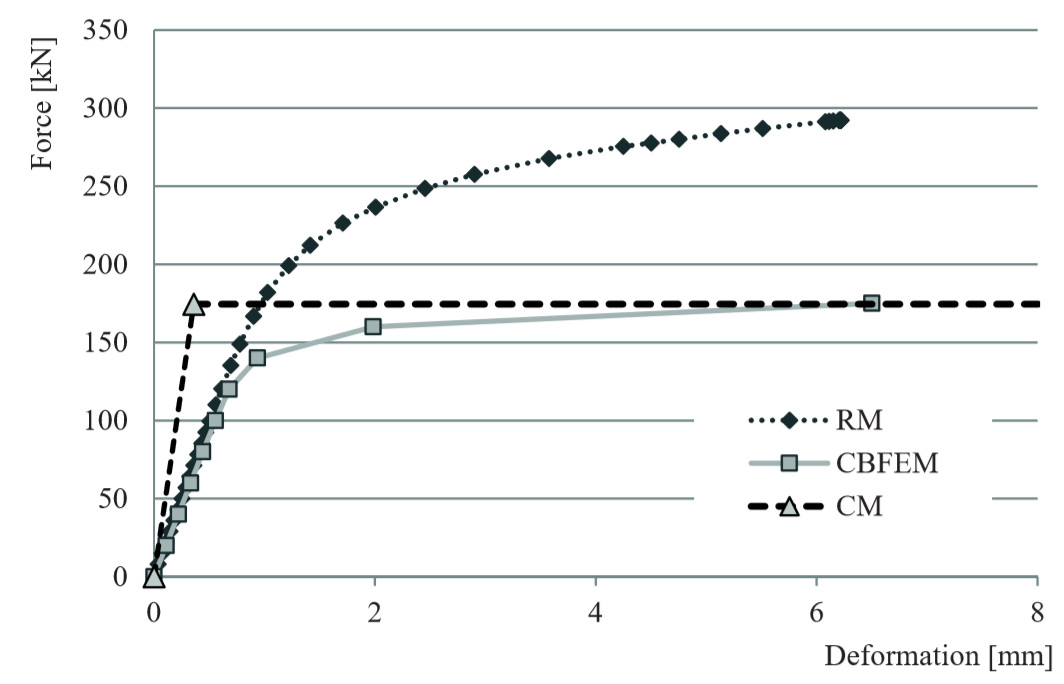

Comparison of the global behaviour of the T-stub described by force-deformation diagrams for all design procedures was prepared. Attention was focused to the main characteristics: initial stiffness, design resistance and deformation capacity. Sample tf20 was chosen to present as reference, see Fig. 5.1.4 and Tab. 5.1.2. CM generally gives higher initial stiffness compared to CBFEM and RM. ln all cases RM gives the highest design resistance as shown in chapter 6. Deformation capacity is compared also. Deformation capacity of T-stub was calculated according to (Beg et al, 2004). RM does not consider cracking of the material so the prediction of deformation capacity is limited.

Fig. 5.1.4 Force-deformation diagram

Tab. 5.1.2 Global behaviour overview

5.1.7. Verification of resistance

Design resistances calculated by CBFEM were compared with the results of CM and RM in the next step. The comparison was focused on the deformation capacity and determination of the collapse mode too. All results are ordered in Tab. 5.1.3. The study was performed for five parameters: thickness of the flange, bolt size, bolt material, bolt space and T-stub width.

Tab. 5.1.3 Global behaviour overview

Fig. 5.1.5 Sensitivity study of flange thickness

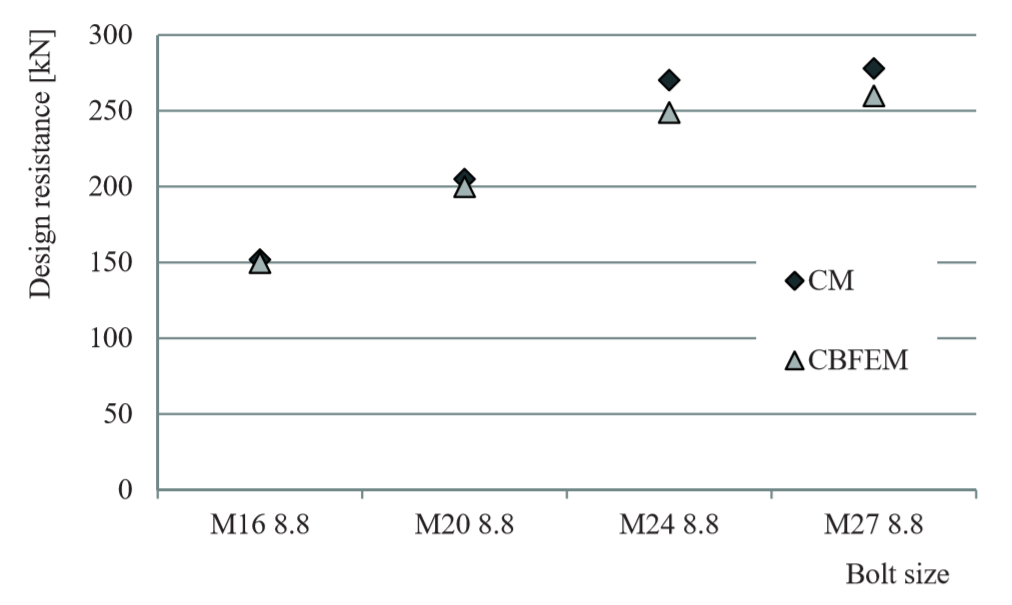

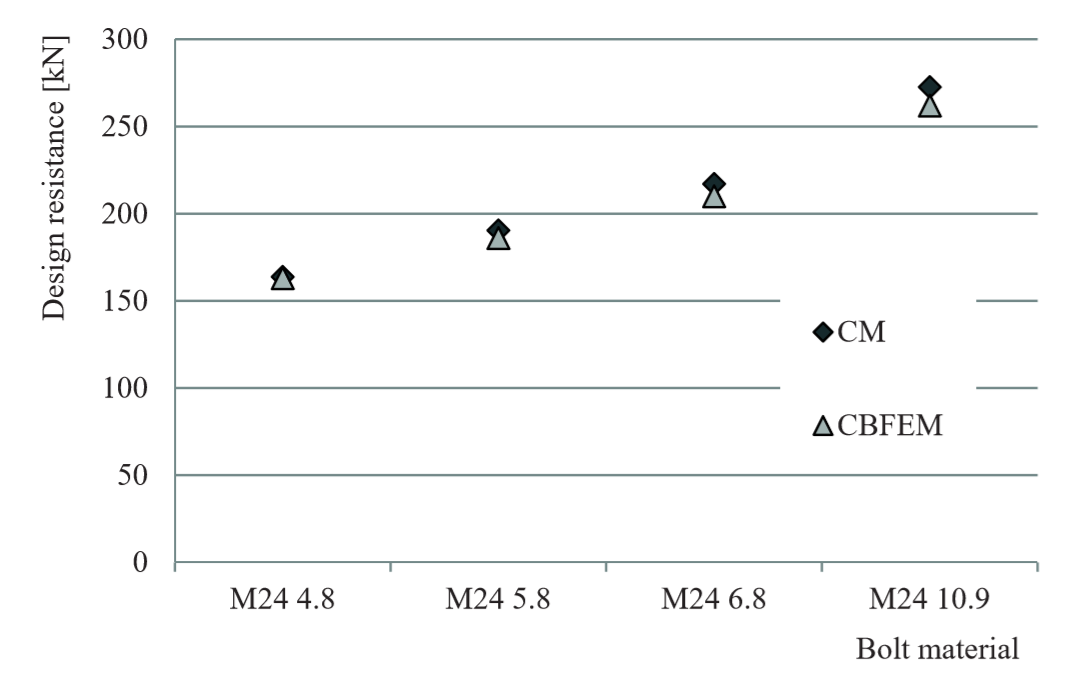

The sensitivity study of thickness of the flange shows higher resistance according to CBFEM compared to CM for samples with flange thicknesses up to 20 mm. RM gives even higher resistance for these samples, see Fig. 5.1.5. Higher resistance of both numerical models is explained by neglecting of membrane effect in CM. ln case of the bolt diameter, see Fig. 5.1.6 and bolt material, Fig. 5.1.7, respectively, correspond results of CBFEM and CM. Due to a good agreement of both methods, results of RM are not required.

Fig 5.1.6 Sensitivity study of the bolt size

Fig. 5.1.7 Sensitivity study of the bolt material

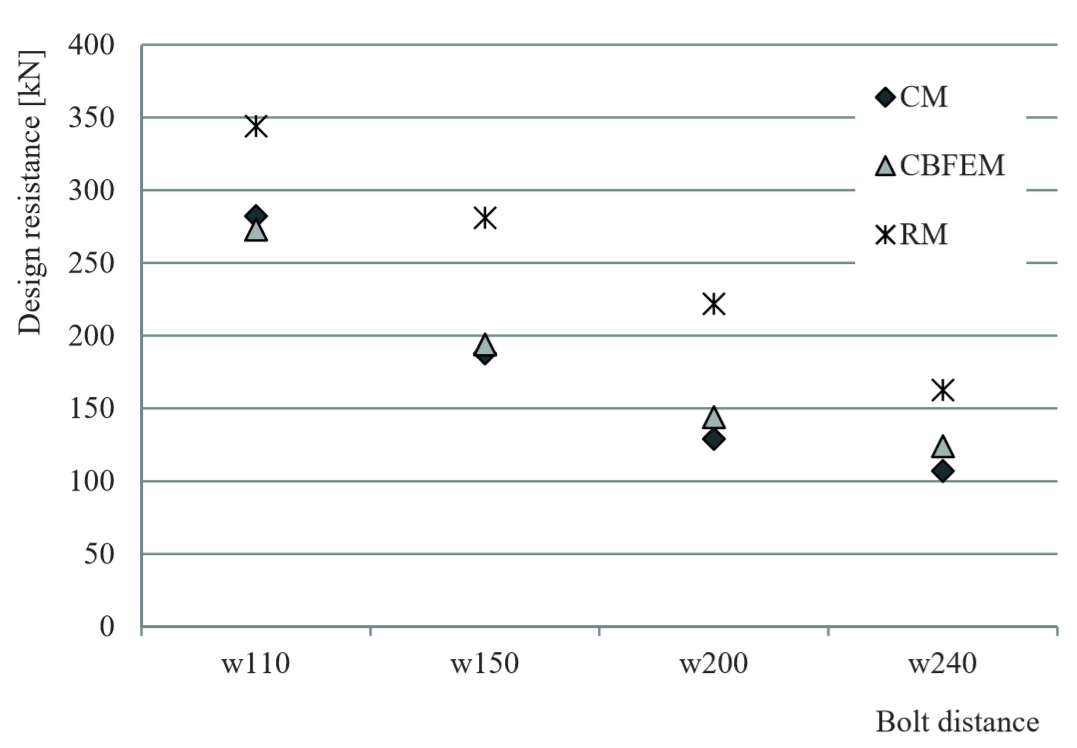

ln the case of the bolt distances results of CBFEM and CM show generally good agreement, see Fig. 5.1.8. With increase of bolt space, CBFEM gives slightly higher resistance compared to CM. For that reason, results of RM are showed also. RM gives the highest resistance in all cases.

Fig. 5.1.8 Sensitivity study of the bolt distance

ln study of T-stub width shows CBFEM higher resistance compared to CM with increase of width. Results of RM were prepared, which gives again the highest resistance in all cases, see Fig. 5.1.9.

Fig. 5.1.9 Sensitivity study of T-stub width

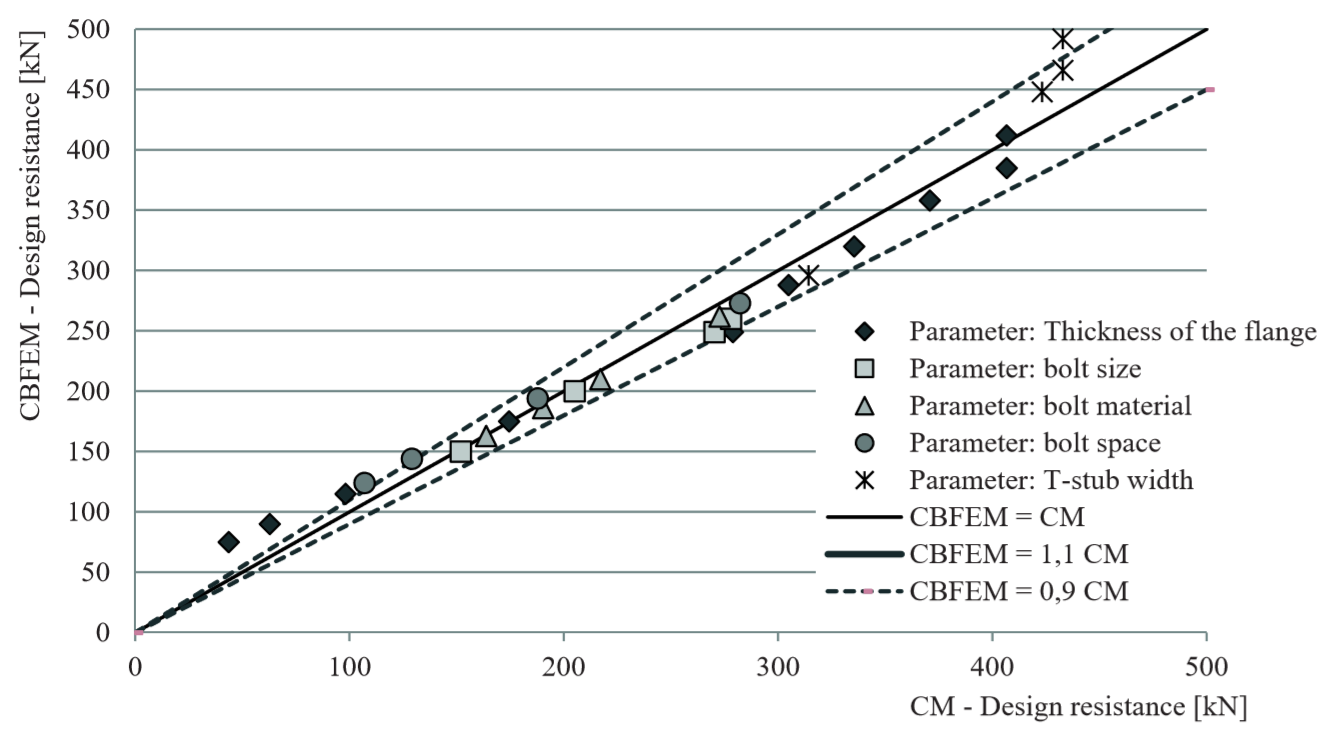

To show the prediction of the CBFEM model, results of the studies were summarized in graph comparing resistances by CBFEM and component method, see Fig. 5.1.10. The results show that the difference of the two calculation methods is mostly up to 10 %. ln cases with CBFEM/CM > 1,1 accuracy of CBFEM was verified by the results of RM which gives highest resistance in all selected cases.

Fig. 5.1.10 Summary of verification of CBFEM to CM

5.1.8. Benchmark example

Inputs

T- stub

- Steel S235

- Flange thickness tf = 20 mm

- Web thickness tw = 20 mm

- Flange width bf = 300 mm

- Length b = 100 mm

- Double fillet weld aw = 10 mm

Bolts

- 2 x M24 8.8

- Distance of the bolts w = 165 mm

Outputs

- Design resistance in tension FT,Rd = 175 kN

- Collapse mode - full yielding of the flange with maximal strain 5 %

- Utilization of the bolts 88,4 %

- Utilization of the welds 49,1 %