4.3.1 Description

In this chapter is verified the component based finite element method (CBFEM) of a fillet weld in a fin plate joint with component method (CM). A fin plate is welded to open section column HEB. The height of the fin plate is changed from 150 to 300 mm. The plate/weld is loaded by normal and shear force and bending moment.

4.3.2 Analytical model

The fillet weld is the only component examined in the study. The welds are designed to be the weakest component in the joint according to Chapter 4 in EN 1993-1-8:2005. The design resistance of the fillet weld is described in section 4.1. Overview of the considered examples and the material are given in the Tab. 4.3.1. Three load cases are considered, i.e. normal force N, shear force V and bending moment M. A geometry of the joint with dimensions is shown in Fig. 4.3.1.

Tab. 4.3.1 Examples overview

Fig. 4.3.1 Joint’s geometry with dimensions

4.3.3 Numerical model

The weld in CBFEM model is described in section 3.4. The nonlinear elastic-plastic material is used for welds in this study. The limit plastic strain is reached in longer part of the weld and stress peaks are redistributed.

4.3.4 Verification of resistance

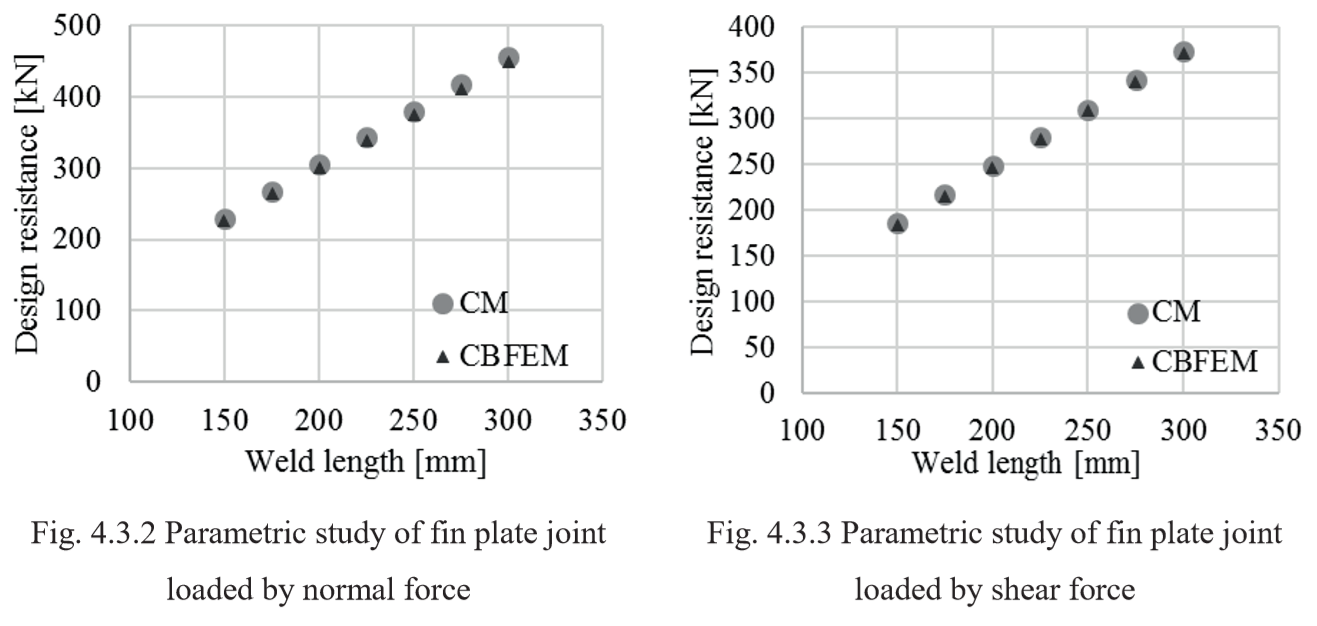

Design resistance calculated by CBFEM is compared with the results of CM. The weld’s design resistances are compared as presented in Tab. 4.3.2. The study is performed for one parameter: length of the weld, i.e. height of the fin plate and three load cases: normal and shear force and bending moment. The shear force is applied in a weld plane to neglect the effect of an additional bending. The bending moment is applied at the end of the fin plate. The influence of the weld length on the design resistance of the fin plate joints loaded by the normal and shear force are shown in Fig. 4.3.2. The relation between the weld length and the bending moment resistance of the joint is shown in Fig. 4.3.3.

Tab. 4.3.2 Comparison of CBFEM and CM

Results of CBFEM and CM are compared and sensitivity study is presented. The influence of weld length on the design resistance in a fin plate joint loaded by normal force is shown in Fig. 4.3.2, by shear force in Fig. 4.3.3 and by bending moment in Fig. 4.3.4. Study shows good agreement for all applied load cases.

To illustrate the accuracy of the CBFEM model, results of the parametric studies are summarized in a diagram comparing the CBFEM’s and CM’s design resistances, see Fig. 4.3.5. The results show that the difference of the two calculation methods is in all cases less than 10 %.

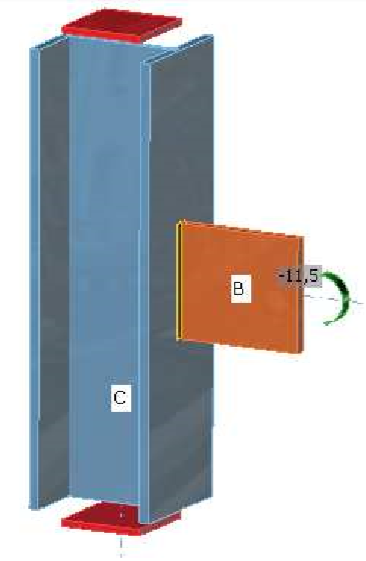

4.3.5 Benchmark example

Inputs

Column

- Steel S235

- HEB400

Fin plate

- Thickness tp = 15 mm

- Height hp = 175 mm

Weld, double fillet weld see Fig. 4.3.6

- Throat thickness aw = 3 mm

Outputs

- Design resistance in poor bending MRd = 11,5 kNm

Fig. 4.3.6 Benchmark example for the welded fin plate joint